German car ownership feels like dating someone gorgeous but high-maintenance—the thrills are real, but the bills pile up fast. Sticking to factory maintenance schedules is like following Emily Post’s etiquette guide at Burning Man: hilariously out of touch. These Teutonic chariots can cruise past 200,000 miles, but only if you know the real maintenance game. These secrets come straight from mechanics who’ve seen cracked cooling systems, carbon-clogged intakes, and enough oil leaks to make Exxon blush.

10. Plastic Cooling System Components

German engineers love plastic parts that self-destruct right after warranty expires.

BMW, Mercedes, and Audi use plastic water pumps, thermostat housings, and overflow tanks. These components become about as structurally sound as week-old sushi after 60,000 to 80,000 miles. What seems like a $50 part turns into a $1,500 repair because the front end needs to come apart. The plastic invasion under the hood means you might be stranded sooner than expected—cracking and leaking is the cooling system’s version of a dad joke.

9. “Lifetime” Fluid Marketing

ZF transmission specs contradict the “lifetime fill” fairy tale automakers love to sell.

Your Beemer needs transmission fluid changes every 60,000 miles—a $300 service that prevents a $4,000 replacement. Differential fluid needs a $150 swap every 50,000 miles to dodge a $2,500 rebuild. “Lifetime” really means “until the warranty expires.” Skip these services, and you’re basically funding your mechanic’s summer house.

8. Oil Filter Housing Gasket (OFHG) Leak Risk

A $200 gasket repair prevents $15,000 engine replacements on BMW and Audi engines.

Oil leaking onto the serpentine belt is like spilling coffee on your laptop—initially a small mess, but it escalates fast. That neglected OFHG leak is basically your engine weeping its life away, drop by expensive drop. German specialists know this game-ending failure pattern and prevent it with a simple gasket swap.

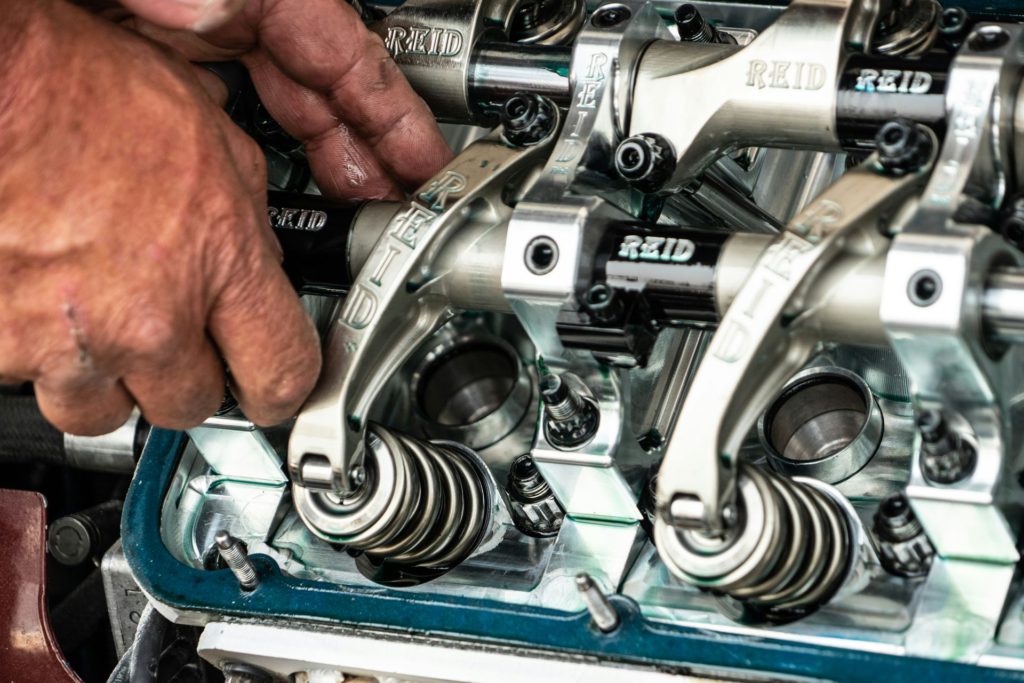

7. Carbon Buildup in Direct Injection Engines

Direct injection engines need intake-valve cleaning despite what your manual claims.

German DI engines require intake-valve cleaning every 60,000 to 80,000 miles because fuel no longer washes over intake valves. Walnut blasting runs $600 to $800, but prevents thousands in engine damage. Those carbon deposits are staging a coup, ready to choke your engine. Regular cleaning keeps engines purring for 200,000-plus miles.

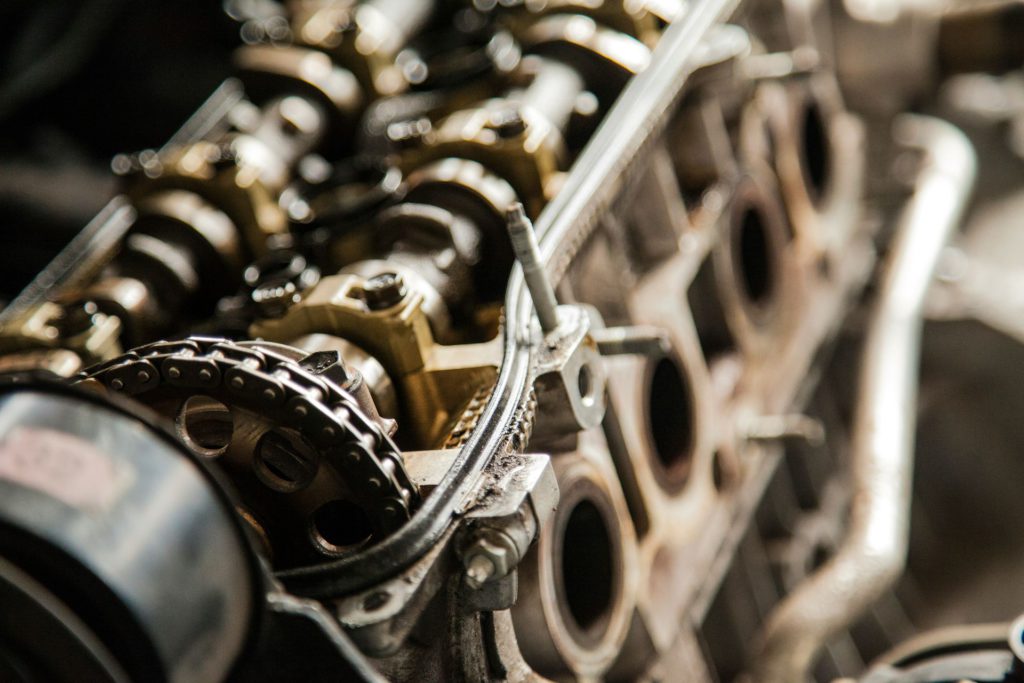

6. Timing Chain Rattling

Cold-start rattles signal imminent catastrophic failure on specific BMW and Audi engines.

Certain BMW and Audi engines develop timing chain rattles between 60,000 to 100,000 miles. Ignoring it is like ignoring that questionable stain in your fridge—it won’t get better with time. A seemingly minor repair becomes a $2,000 to $4,000 tensioner and guide replacement if you wait too long.

5. Proprietary Software Lockout

Simple brake jobs now require dealer software just to reset electronic parking brakes.

Even basic brake pad jobs can morph from a $50 DIY to a $300 software-locked service. Try registering a new battery without the mothership’s blessing—suddenly that $150 fix jumps to $400. Automakers claim it’s about quality control, but it feels more like turning your car into a subscription service.

4. Crumbling Suspension

Performance-tuned suspensions prioritize handling over durability, creating expensive replacement cycles.

German performance cars need suspension bushings replaced every 60,000 to 80,000 miles, costing $2,000 to $4,000. Air suspension systems require $6,000 to $10,000 in repairs every 80,000 to 100,000 miles. Those air springs are basically fancy balloons that eventually become the automotive equivalent of a Kardashian—high maintenance and prone to dramatic collapses.

3. High-Pressure Fuel Pump (HPFP) Surprise

That metallic whine around 100,000 miles signals your HPFP’s expensive swan song.

The HPFP on direct-injection German engines operates at insane pressures, making it as sensitive as your uncle’s IBS after Thanksgiving dinner. Parts alone run $1,500 to $2,500, with labor adding another $1,000 to $1,500 because German engineers designed these cars with a Rubik’s Cube in mind. When it fails, you’re cruising one moment and stranded the next.

2. Dealership Maintenance Schedule Deception

Factory intervals optimize lease costs, not long-term reliability.

Dealerships suggest oil changes every 10,000 to 15,000 miles and “lifetime” transmission fluid. If you’re keeping your German ride past warranty, that’s like trusting a Tinder bio—believe half of what you read. Change oil every 5,000 to 7,500 miles, swap transmission fluid every 50,000 miles, and refresh spark plugs every 60,000 miles instead of waiting for 100,000 miles.

1. Buried Alternators and Starters

German weight distribution priorities turn simple repairs into expensive archaeological digs.

German engineering prioritizes crash safety and weight distribution over easy access. A $300 alternator replacement morphs into a $1,500 nightmare requiring major disassembly. Getting to buried starters requires the kind of teardown usually reserved for IKEA furniture—only pricier. A $200 starter becomes a $1,200 repair thanks to service bay gymnastics.

Last modified: January 9, 2026